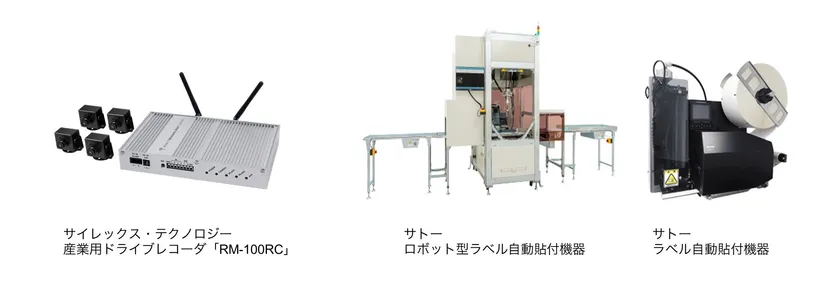

SATOH's automatic label applicator is now available as an option, Silex's industrial drive recorder is used as an option for SATO's automatic label applicators.

- Enables rapid root cause investigation and countermeasures in the event of production line malfunctions.

サイレックス・テクノロジー株式会社

Silex Technology, Inc. (Headquarters: Seika-cho, Kyoto; President: Nobuhiko Miura; hereinafter "Silex") announces that Silex's RM-100RC industrial drive recorder has been adopted as an optional product for SATO Corporation's (Headquarters: Minato-ku, Tokyo; President: Yoshinori Sasahara; hereinafter "SATO") robot-type automatic label applicators. (head office: Minato-ku, Tokyo; president: Yoshinori Sasahara; hereafter, "Sato") has adopted Silex's RM-100RC industrial drive recorder as an optional product for its robotic automatic label applicators.

Silex Industrial Drive Recorder Adopted as an Option for SATO's Automatic Label Applicator

Background of Adoption

In the manufacturing and logistics industries, there is a growing need to improve efficiency and traceability. In particular, stable operation of label application operations has become an important issue. S-ROBO Pro, one of Sato's automatic label applicators, is a machine that reads the shape and position of the product with a 3D camera and applies stickers and labels at high speed. It is not necessary to feed the products in the same direction, and stickers and labels can be applied accurately even if the products are unevenly shaped. In the unlikely event of a breakdown or malfunction during operation, the RM-100RC industrial drive recorder from Silex is used to quickly confirm the operating phenomenon based on video recordings and to quickly restore the customer's production line.

Effects of adopting the RM-100RC

The introduction of Silex's RM-100RC industrial drive recorder has facilitated the identification of the operating status of the automatic label applicator and the cause of any trouble. In addition to the "S-ROBO Pro," the following effects were achieved with the automatic label applicators including the "Tough Arm Series.

Improvement of traceability

By recording the entire label application process, it is possible to quickly identify the cause of any problems and take countermeasures, contributing to improved product quality.

Improved work efficiency

Real-time monitoring of the operation status of automatic label applicators facilitates maintenance planning and reduces downtime.

Enhanced data management

By utilizing the collected video data, the RM-100RC identifies areas for improvement in the business process and promotes continuous improvement of operations.

Outline of RM-100RC

The RM-100RC is a multi-camera drive recorder for industrial sites that records troubles and events in automated equipment and production lines in factories and warehouses. It can record with up to four cameras at once, and allows efficient condition monitoring by setting the recording mode and storage method to suit the application and by recording before and after times centered on the trigger. The RM-100RC also allows users to check camera images and monitor the system from a wireless terminal such as a tablet PC using the RM-100RC's access point function, even if there is no network on site.

RM-100RC

RM-100RC product page: https://www.silex.jp/products/monitoring/list/rm100rc

RM-100RC press release and product image download: https://www.silex.jp/backnumber/press/20240228

■Related Information

SATO's robotic automatic label applicator and Silex's RM-100RC will be exhibited in the SATO booth at the International Logistics Exhibition 2024 to be held at Tokyo Big Sight from September 10 (Tue) to 13 (Fri), 2024.

About SATO Corporation

The SATO Group is a global corporate group established in 1940, which operates its business in more than 90 countries and regions. Using barcodes, RFID, and other technologies for automatically recognizing and inputting/outputting information (automatic-recognition technology), Satoh transforms everything in the real world into information, and by utilizing this information, provides a system for optimal problem solving for each site (consolidated sales of 143.4 billion yen as of the end of March 2024). (Consolidated net sales of 143.4 billion yen as of March 31, 2024).

Location: msb Tamachi Tamachi Station Tower N, 3-1-1 Shibaura, Minato-ku, Tokyo

Representative: Yoshinori Sasahara, President and Representative Director

Capital : 4 billion yen

Company website : https://www.sato.co.jp/

Business Description: Automatic identification solution products (label printers, RFID printers, automatic laminating robots, software, seals and labels),

automatic labeling robots, software, stickers and labels, RFID tags, hand labelers, etc.),

hand labelers, etc.), planning, development, design, manufacturing, sales, and maintenance.

Planning and proposal of comprehensive solutions combining barcode readers, RFID readers, and other peripheral devices from other companies.

Silex Technology, Inc.

About Silex Technology

Silex Technology, Inc. is an R&D-oriented company with hardware and software technologies at its core. The company provides products and services that build wireless environments with reliable connectivity for customers' devices and systems in the medical and industrial fields using secure and reliable wireless technologies and embedded know-how, and realizes the best individual customer experience through the creation of "uninterruptible wireless spaces. Through our offices in North America, Europe, China, and India, we are expanding our business globally by collaborating with overseas partners and developing new markets. We maintain strict quality standards by controlling a series of processes from design and development to production and quality assurance at our "Keihanna Headquarters." At the same time, we respond to diverse customer needs in each region and provide local custom engineering under a development system in collaboration with our overseas bases.

- Category:

- Corporate Trends