Environmentally conscious brand uses robotic arm 3D printer to create large scale decorative wall for event booth.

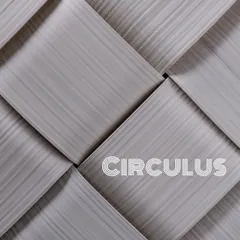

3D Printing Technology x Sustainable Materials “CIRCULUS” is an atelier that transforms architecture into a recycling-oriented society.

Oka Architecture Design & Co.,Ltd.

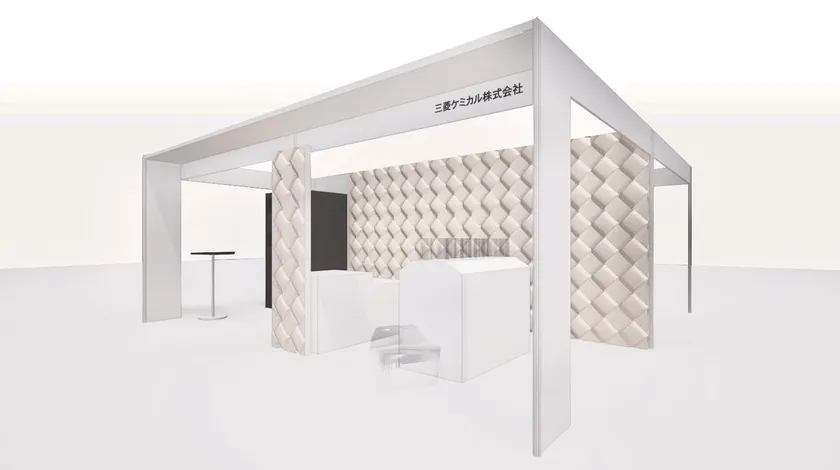

Tokyo, September 26th and 27th: Oka Yuko Architecture Design & Co.,Ltd. (Location: Yokohama, Japan. President: Yuko Oka), an atelier for developing renewable architectural products using 3D printing technology and sustainable materials, will be exhibiting a large decorative wall using Mitsubishi Chemical products at the "Formnext Forum Tokyo 2024." The exhibition is to be held at the Tokyo Metropolitan Industrial Trade Center Hamamatsucho Pavilion.

In the future, Oka Architecture Design intends to develop products that meet the fire-retardant specifications of the Building Standard Law and other regulations in Japan, so that they can be used in various architectural applications.

Mitsubishi Chemical Corporation exhibition booth perspective

■What is Atelier "CIRCULUS"? https://www.circulus.design/

Atelier "CIRCULUS," named after the Latin word meaning "circle," is a design brand that aims to transform architecture into a recycling-oriented system. In response to the current situation in which many buildings are demolished after use and become waste, the concept is "from architecture that is demolished and discarded into architecture that circulates."

CIRCULUS uses a robot arm 3D printer to design and create furniture, interior finishes, art, and other products using synthetic resin. After use, the products can be ground into pieces and printed into new forms. By utilizing large-scale 3D printing technology, which is still largely unused in Japan, it is possible to reduce carbon dioxide emissions associated with the transportation of building materials as well as circulate resources within the local region. CIRCULUS is playing a part in paving the way for the future of sustainable architecture during the building lifecycle, from design to demolition.

■Japan's largest robotic arm 3D printer opens up the future of recycling-oriented design.

The atelier "CIRCULUS" is equipped with Japan's largest robotic 3D printer developed by a Swedish integrator.

Compared to the 3-axis gantry type, the robotic arm type has a higher degree of freedom and can handle more complex and unique designs. The materials used include Mitsubishi Chemical's Tefabloc(TM) TPS, which improves processability and enables advanced designs while maintaining an aesthetically pleasing appearance. Furthermore, with 3D printing there is zero waste because there is no cutting of the material. No molds are required, making it ideal for high-mix, low-volume production. In addition, recyclable synthetic resins are used, and after the exhibition, the products are ground up and reborn into new forms, making it possible to achieve resource recycling. Furthermore, the atelier operates on 100% natural energy with zero CO2 emissions, pursuing an environmentally friendly manufacturing process.

CIRCULUS was selected as one of 11 finalists worldwide in the 3D Printing FGF Engineering Challenge by the Mitsubishi Chemical Group.

CIRCULUS robotic arm printer

CIRCULUS Robotic Arm Printer 2

■Formnext Forum Tokyo 2024

Event name: Formnext Forum Tokyo 2024

Date:Thursday, September 26 - Friday, September 27, 2024 10:00-17:00

Venue: Tokyo Metropolitan Industrial Trade Center Hamamatsucho Building

Access: 5 min. walk from JR Hamamatsucho Station

Details: https://formnextforum.jp.messefrankfurt.com/tokyo/ja.html

<About the Exhibits>

In this exhibition, visitors will be able to experience designs that make full use of CIRCULUS' 3D printing technology. "KNIT" placed at the back, and the center of the front of the building is a recyclable facade panel system with beautiful shades of lines created by 3D printing. It creates a three-dimensional effect on the wall surface, like a fine-quality textile.

In addition, a precisely crafted watermark screen is installed on the left side of the main entrance, creating a soft and gentle atmosphere enhanced by the natural texture of the resin.

KNIT" details: https://www.circulus.design/knit

Renewable facade "KNIT

Shade created by "KNIT

■Company Profile

Company Name: Oka Yuko Architecture Design, Inc.

Address: B01 Bashamichi Otsu Building, 4-43 Minaminakadori, Naka-ku, Yokohama, Kanagawa 231-0006, Japan

President :Yuko Oka

Establishment : March 2009

Business : Design and supervision of architectural projects, interior design

URL :Company website https://www.o-a-d.co.jp

Instagram: Company https://www.instagram.com/o.a.d.co.ltd/

CIRCULUS https://www.instagram.com/circulus.design/

For inquiries regarding this matter, please contact:

Oka Yuko Architecture Design, Inc.

TEL : 045-319-4425

E-mail: info@o-a-d.co.jp

- Category:

- Corporate Trends