Toyo Shinyaku further strengthens quality assurance system ”Stealth Printer" introduced to all lines, greatly improving traceability

”Near-infrared Analysis Method" and "Atomic Absorption Spectrophotometer" have been newly introduced to reduce the risk of foreign material contamination.

Toyo Shinyaku Co., Ltd.

Toyo Shinyaku Co., Ltd. (Head Office: Fukuoka City, Fukuoka Prefecture; Headquarters: Tosu City, Saga Prefecture; President: Toshimitsu Hattori), a comprehensive contract manufacturer of health foods and cosmetics, has introduced ”Stealth Printer" to all health food production lines to further strengthen its quality assurance system. In addition, the company has also speeded up its response to contamination by foreign substances by enhancing its ”Near-infrared Analysis Method" and introducing "Atomic Absorption Spectrophotometer".

As a contract manufacturer of health foods and cosmetics, Toyo Shinyaku has established strict quality standards from the selection and procurement of raw materials to the design, development, manufacture, and shipment of products based on its corporate philosophy of "Consumer safety comes first, above all else, at all times. We have recently introduced new equipment to further strengthen our quality assurance system.

First, in order to enhance product safety and reliability, we have introduced ”Stealth Printer" to all health food production lines at the Tosu Plant and Intelligence Park Plant No.1. This equipment will greatly improve product traceability. ”Stealth Printer” prints information with invisible ink, making it invisible to consumers, yet allowing for quick reading of necessary information (e.g., production time in minutes, order of production, etc.) during the manufacturing and distribution processes. This allows us to respond quickly and accurately in the event of a quality problem.

We have also enhanced our ”Near-infrared Analysis Method" (NIR) and introduced a new "Atomic Absorption Spectrophotometer". With these analytical instruments, we aim to improve the inspection accuracy of raw materials and further reduce the risk of foreign material contamination. In particular, the "Atomic Absorption Spectrophotometer" is superior in its ability to detect minute amounts of metal contamination, making it possible to further enhance product safety against metal contamination.

■Outline of Facilities

(1) Traceability Improvement

Stealth Printer andprinting example

Name of machine: Stealth Printer

Stealth Printer prints information on products using transparent "Stealth Ink," which is normally invisible. The printed information can be visually confirmed only when irradiated with ultraviolet rays.

Introduction date: October 2024 (to be introduced to all health food production lines).

Advantages: While normally tracking is done on a lot-by-lot basis, stealth printing enables more detailed tracing on a minute-by-minute basis and in the order of production, enabling a quick response when quality problems occur. It is also effective as a countermeasure against damage caused by counterfeit products.

(2) Reduction of Foreign Material Contamination Risk

Near-Infrared Analysis (NIR) Gun Type

Name of machine: Near-Infrared Analysis (NIR) Gun Type

Checks whether the peak waveform matches the waveform stored in the library. If the waveforms match, they are determined to be from the same raw material. If not, and the peak positions and waveforms are significantly different, the contents are different or foreign material is mixed in.

Enhancement date: October 2024.

Advantage: The identity of raw materials used in manufacturing can be confirmed in a non-contact manner prior to the manufacturing stage.

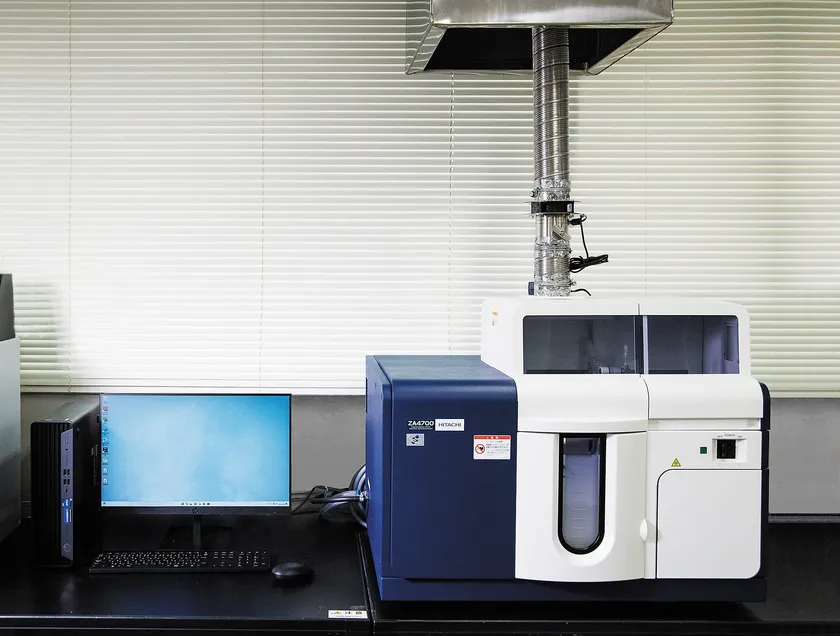

Atomic Absorption Photometer

Name of machine: Atomic absorption spectrophotometer

The Atomic Absorption Spectrophotometer measures the absorption spectrum of a sample to determine the presence of arsenic, lead, and other harmful metals in the sample.

Introduction date: October, 2024.

Advantages: It is possible to confirm that no harmful metals are contained in raw materials and products. Analysis can be performed in a shorter period of time than with conventional methods.

As an ODEM (ODM & OEM) manufacturer of health foods and cosmetics, Toyo Shinyaku will continue to strengthen its quality assurance system, provide products that consumers can use with confidence, and contribute to the "health" and "beauty" of people worldwide.

Company Profile

Company name: Toyo Shinyaku Co., Ltd.

Establishment: September 18, 1997

Representative: Toshimitsu Hattori, President and Representative Director

Business Description: Contract manufacturing, sales, research, and development of health foods, functional foods, Tokuho (food for specified health uses), cosmetics, and quasi-drugs.

Home Page: https://www.toyoshinyaku.co.jp/

~Location~

Headquarters and Tosu Plant: 7-28 Yayogaoka, Tosu City, Saga Prefecture

Intelligence Park: 3-1-2 Yayogaoka, Tosu City, Saga Prefecture

Head Office, Fukuoka Branch: 2-19-27, Hakata Ekimae Building, Hakata-ku, Fukuoka City, Fukuoka Prefecture

Tokyo Brunch: Sumitomo Fudosan Shibuya First Tower, 1-2-20 Higashi, Shibuya-ku, Tokyo

Osaka Brunch: JP Tower Osaka, 3-2-2 Umeda, Kita-ku, Osaka-shi, Osaka

About Toyo Shinyaku Co., Ltd.

TOYO SHINYAKU is a general contract manufacturer of health foods and cosmetics founded in 1997, and has developed a new business model called "ODEM (ODM)" based on both ODM (Original Design Manufacturing) and OEM (Original Equipment Manufacturing). We respond quickly to our customers' various requests by providing consulting services for all aspects of our business and total support from product planning, product design, formulation development, manufacturing, delivery, and sales promotion support. Our research and development department is capable of searching for functional ingredients, conducting efficacy and safety tests, and conducting clinical trials, and we are No. 1 in the number of Foods for Specified Health Uses (Tokuho) approved products, and we have an abundant track record of submitting applications for Foods with Functional Claims. In addition, our manufacturing plant is the first to comply with cGMP (U.S. GMP for appropriate management of manufacturing, packaging, labeling, and storage of dietary supplements) as a comprehensive contract manufacturer in Japan, and we have also acquired various certifications and accreditations such as Dietary Supplement GMP, FSSC22000, and ISO22716, We have established a quality control system that meets international standards.

For more information, please refer to https://www.toyoshinyaku.co.jp/.

The " TOYO SHINYAKU " brand logo is a registered trademark of Toyo Shinyaku Co., Ltd.

For inquiries, please contact

Toyo Shinyaku Co., Ltd.

- Category:

- Corporate Trends

- Genres:

- Technology Food & Beverage Economy(Japan)