International Rechargeable Battery Expo to be held at Tokyo Big Sight from February 19 to 21, Exhibiting a device to optically measure the coating condition of electrode sheets for rechargeable batteries

八光オートメーション株式会社

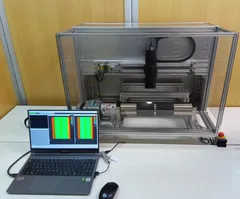

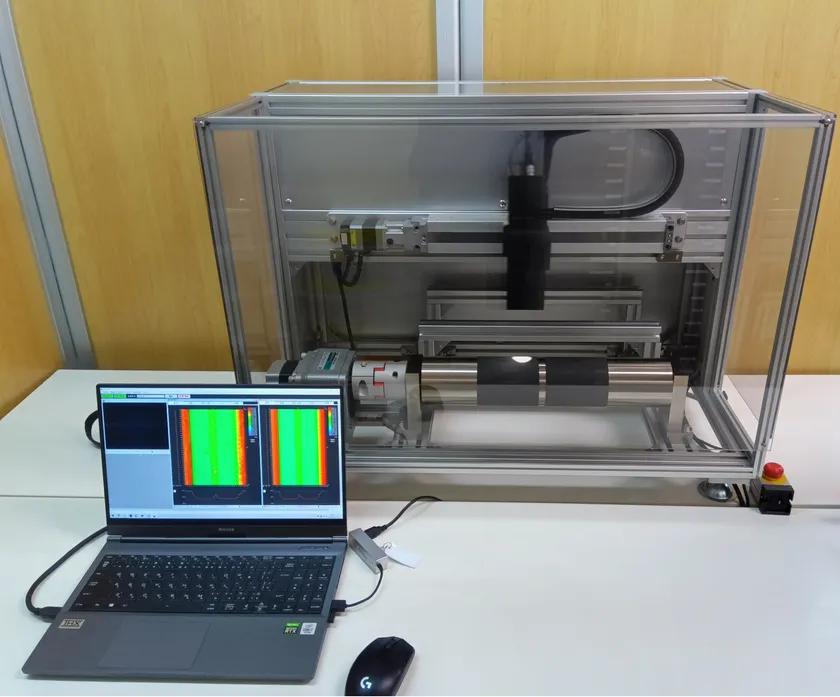

Hakko Automation Co. (Location: Kasuya-cho, Kasuya-gun, Fukuoka Prefecture; President: Kazuo Ono), a company that handles planning, production, and management related to factory automation, has developed RSCIM, a device that optically measures the coating condition of electrode sheets for rechargeable batteries. This device will be exhibited at the 18th International Rechargeable Battery Expo to be held at Tokyo Big Sight from February 19 (Wed.) to 21 (Fri.), 2025.

Coating Condition Measurement System

■Outline

Lithium-ion rechargeable batteries are used in a variety of applications, such as in-vehicle batteries for EVs (electric vehicles) and HEVs (hybrid electric vehicles) and mobile devices, and research and improvements are being conducted to further downsize, increase capacity, and improve safety.

The coating film of the electrode sheet that makes up the battery has a great deal to do with capacity, voltage, and rate characteristics (charge-discharge characteristics), and must be coated continuously and evenly to ensure mass production with the designed performance and specifications. Uneven coating, if it should occur, will greatly affect the quality and performance of the product, so it is important to measure and control the coating surface inline at high speed and with high accuracy.

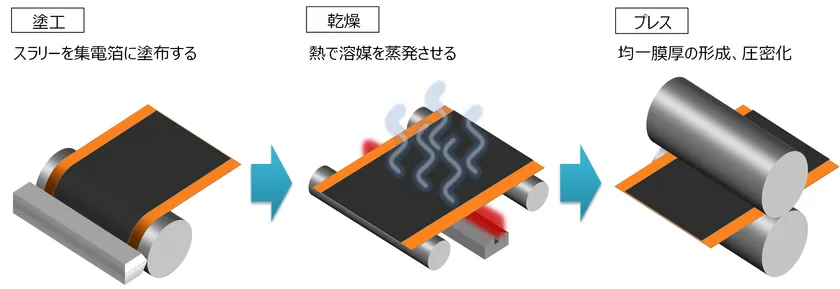

Coating Process

Traditionally, a measurement device using radiation has been used to inspect the coating process, but since it can only measure the amount of coating, a new sensor that can measure the surface condition after pressing has been required.

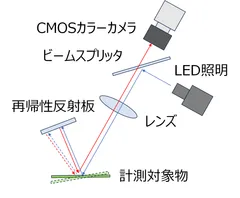

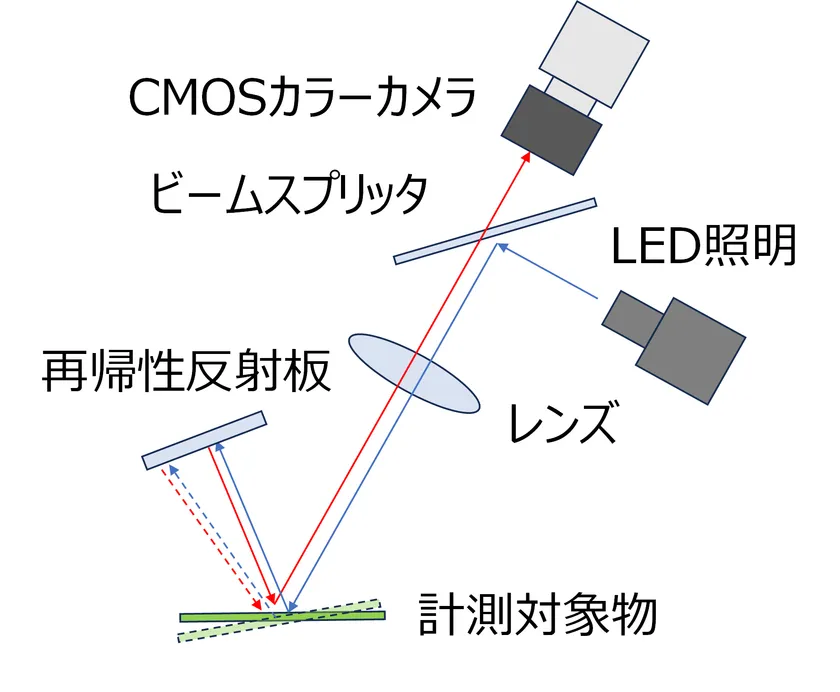

The newly developed RSCIM can measure the surface condition of the electrode sheet after pressing by using the reflection of light.

It analyzes slight changes in the reflected light and measures differences in surface conditions.

Principle diagram

■Measurement Example

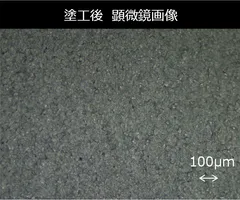

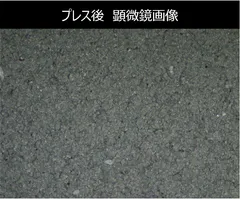

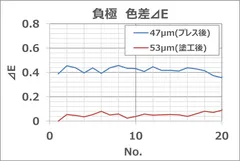

This is an example of measuring the surface of an electrode sheet before and after pressing.

It is difficult to confirm the difference in surface condition due to pressing from the microscope image.

After coating Microscope image

After pressing Microscope image

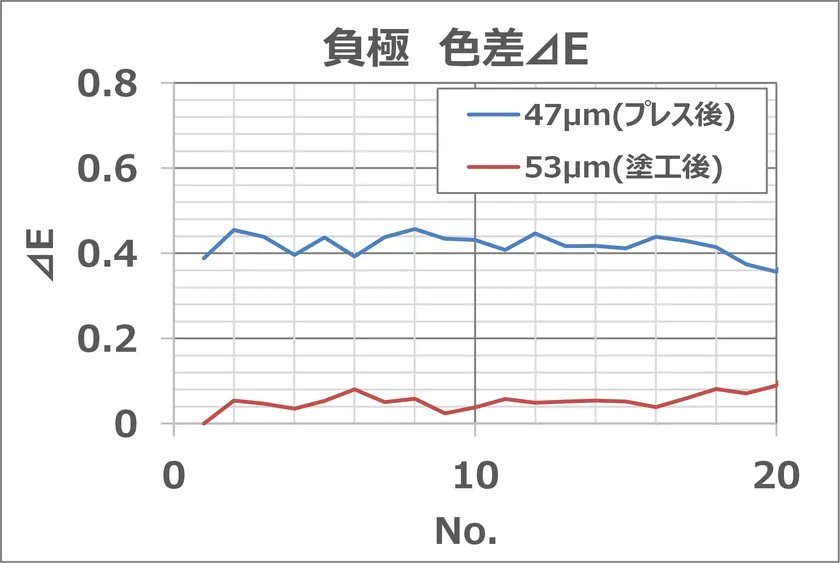

However, the RSCIM measurement can capture the difference in the color difference of the reflected light. This is a result of the change in surface reflectance due to the reduction of surface roughness and the reduction of coating thickness by pressing. By feeding back these measurement results to production facilities, it is possible to manufacture high quality, high performance rechargeable batteries.

Hue graph

Exhibition Information

Exhibition Title : 18th International Rechargeable Battery Expo

Dates : February 19 (Wed.) - 21 (Fri.), 2025

10:00-17:00

Venue: Tokyo Big Sight (3-11-1 Ariake, Koto-ku, Tokyo)

Booth No.: E48-34

<For more information, please visit

https://www.wsew.jp/spring/ja-jp.html#/

Company Information

Founded in 1968, this company handles all processes related to factory automation, from planning to production and management.

The company has a development section, which is rare among small and medium-sized companies, and develops products with its unique core technologies such as microwave, airborne ultrasonic, and image processing.

Company Name : Hakko Automation Co.

Location : 2753-5 Oaza-Nakahara, Kasuya-cho, Kasuya-gun, Fukuoka 811-2304, Japan

Establishment : 1968

Capital : 30 million yen

Number of employees : 88

Website : https://www.hacmat.co.jp/

- Category:

- Corporate Trends

- Genres:

- Technology General Business Economy(Japan)