WEF Technology Development Succeeds in Treating High Concentration PFAS with In-house Technology Enabled low-cost, maintenance-free, long-term, high-volume treatment

WEF技術開発株式会社

WEF Technology Development Co. (Location: Otsu City, Shiga Prefecture; President: Akira Aoyama), which is engaged in the development of technologies for local production and local consumption of water, energy, and food, has succeeded in removing PFAS (Polyfluorinated organic compounds) from water, which has become a problem worldwide. There are two types of treatment technologies, both of which are low-cost and virtually maintenance-free, and are expected to be used for large-scale water treatment applications.

PFAS treatment: Reversing the established theory of PFAS treatment

PFAS, also known as "forever chemicals," are chemicals with high heat resistance and chemical stability. According to the view of the Ministry of Health, Labor and Welfare, PFAS cannot be expected to be removed by conventional water purification methods (coagulation sedimentation filtration, ozone treatment, disinfection treatment, etc.).

For example, "When the amount of sulfate band added in coagulation sedimentation is as high as 110 mg/L, about 30% of PFOA/S can be recovered, but under normal addition conditions, recovery is not expected. The reaction of OH radicals (OH, E0 = 1.9-2.85 V, E0 is the standard redox potential) with organic substances is an addition reaction to unsaturated bonds between carbon atoms, a substitution reaction at aromatic rings, and the withdrawal of hydrogen from target molecules. AOP by OH radicals is invalid for PFOA/S, which has neither unsaturated bonds between carbon atoms, aromatic rings, nor nonionic hydrogen" (Review (refereed) "History and Recent Trends in Research and Development of Technology for Degradation of PFOS and PFOA in Water").

Our patented technology that utilizes coagulation sedimentation and active oxygen, which is said to be impossible to treat according to the conventional theory, has now been confirmed to be capable of coagulation sedimentation or active oxygen decomposition of high concentration PFOA/S.

Treatment test results

First, the results of the treatment are described below.

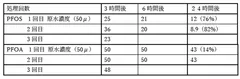

1) Coagulation sedimentation treatment using the treatment agent "TERRAST

PFOS: Raw water concentration (50 μg/L) - (24H treatment) → 3.6 μg/L (93% removal)

PFOA: raw water concentration (50 μg/L) - (24H treatment) → 12 μg/L (76% removal)

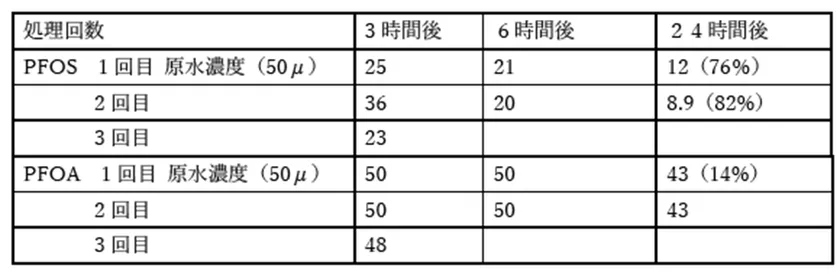

2) Active oxygen catalyst treatment

PFOS: Raw water concentration (50 μg/L) - (24H treatment) → 10.5 μg/L (79% removal, average of 2 treatments)

PFOA: Raw water concentration (50 μg/L) - (24H treatment) → 43 μg/L (14% removal, average of 2 times)

*Treatment was confirmed with high concentration of PFAS. Except for PFOA caused by reactive oxygen species, the treatment results were very effective.

≪Treatment by "TERRAST" treatment agent≫ (1) Treatment by "TERRAST" treatment agent

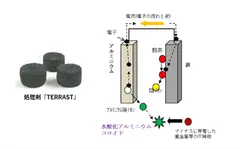

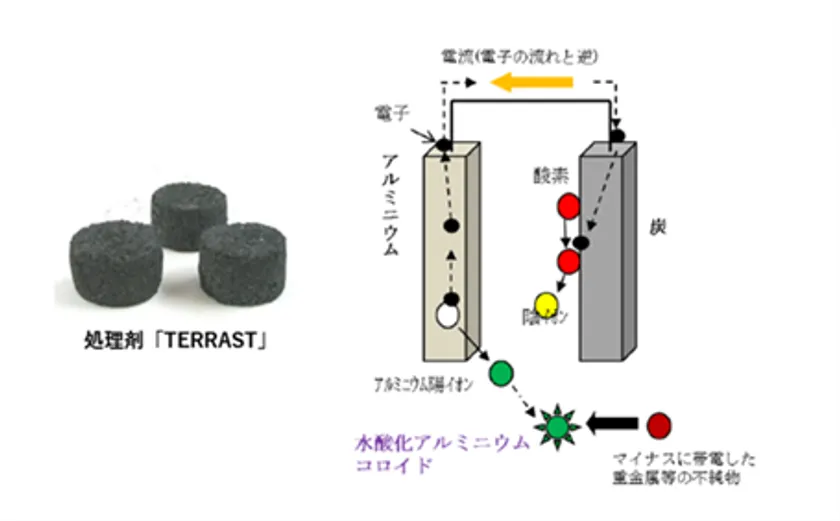

(1) What is the treatment agent "TERRAST"?

TERRAST" is made by solidifying special charcoal and aluminum adhered particles into tablet form with many gaps between them. Aluminum ions are immediately generated into aluminum hydroxide colloids, and since these colloids are positively charged, negatively charged metals and other impurities in the aqueous solution are electrically attracted to the aluminum hydroxide colloid surface, adsorbed and precipitated.

Image (1) TERRAST and treatment mechanism

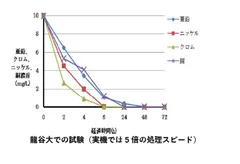

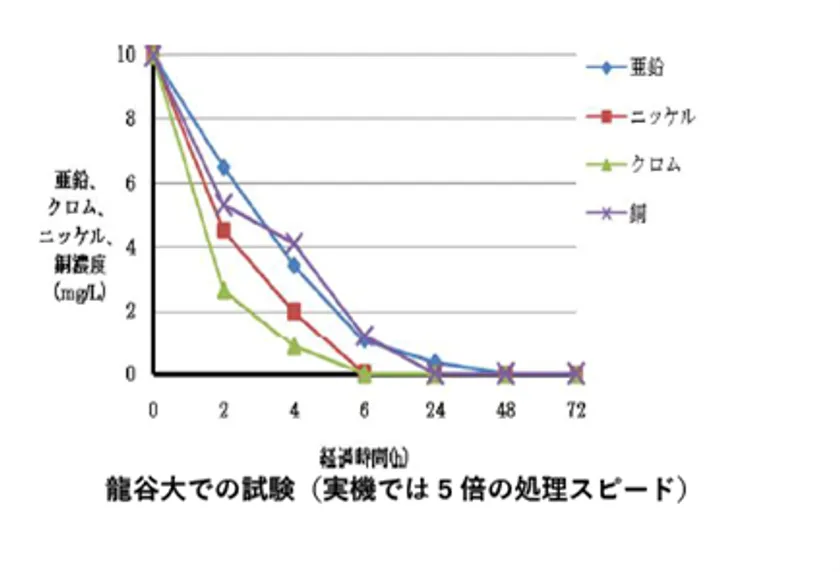

(2) Treatment effect

Image (2) Treatment effect

Features of TERRAST treatment

Efficient coagulation treatment of most heavy metals, fluorine, antimony, mercury, cadmium, arsenic, etc.

Stable elution of aluminum ions for 6 months

・Low concentration treatment is also possible.

Very little precipitation is generated.

PFAS treatment with TERRAST

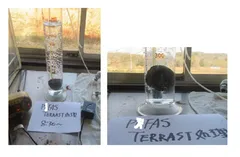

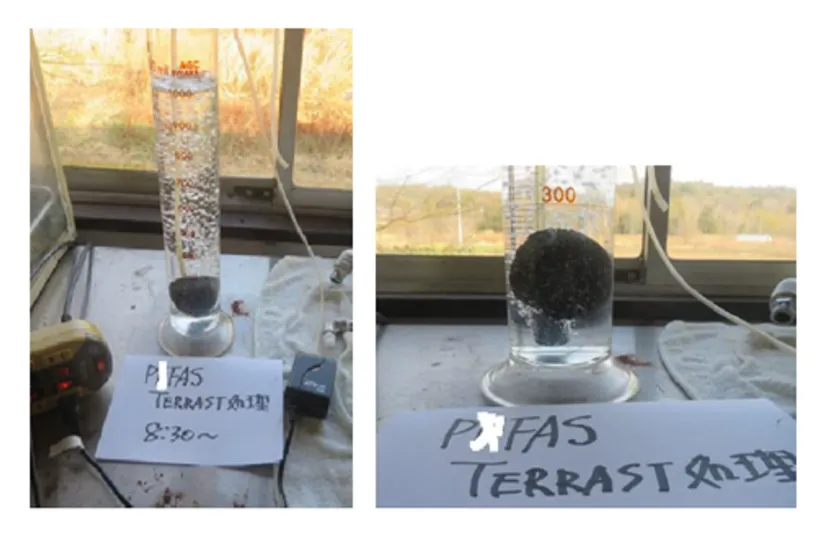

A test solution containing PFOS (50 μg/L) and PFOA (50 μg/L) was prepared by an analytical laboratory. The prepared solution was placed in a 1L female cylinder containing one "TERRAST" and stirred by aeration.

Image (3) TERRAST test

Aluminum ions eluted from "TERRAST" become aluminum hydroxide, which coagulates and precipitates PFAS.

The coagulation and precipitation effect is so great that no subsequent treatment such as polymer coagulant is required, as is the case with other coagulants.

Therefore, the precipitated material generated is almost exclusively the material to be treated, and in the case of PFAS treatment, we believe that only withdrawal at the time of "TERRAST" replacement (6 months) is required.

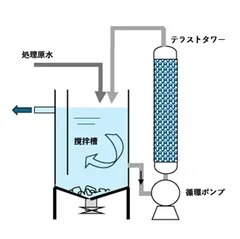

◆Treatment process and delivery record

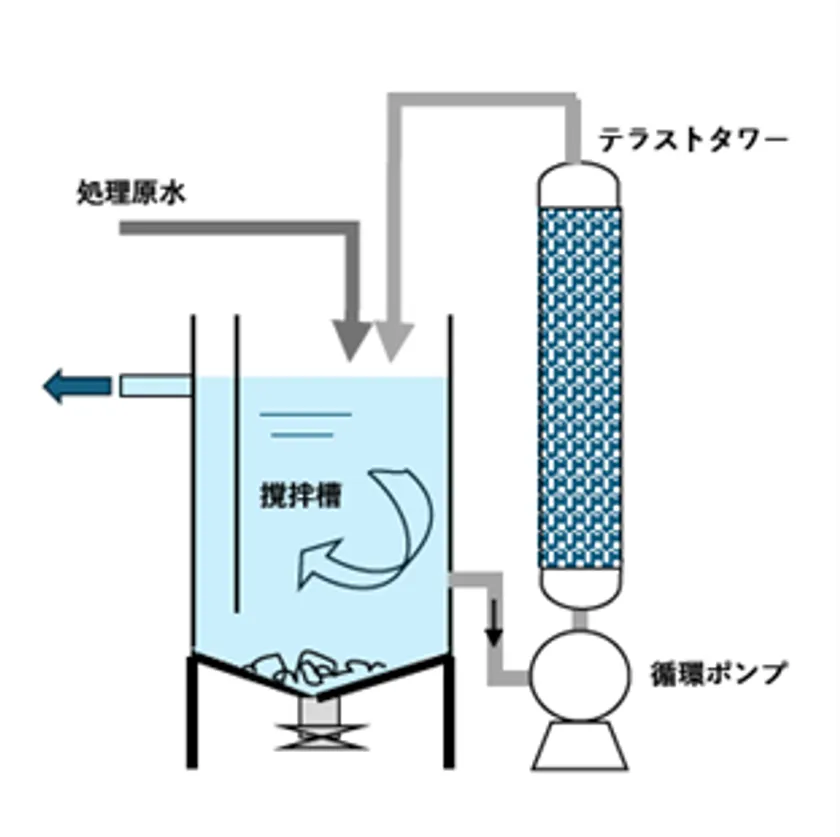

Image (4)Treatment process

Image (5) Delivery record

≪PFAS treatment by active oxygen catalyst -What is active oxygen catalyst treatment?

The world's leading technology generates active oxygen from oxygen in the air, to which a small amount of ozone is added to create ionized ozone (ozonide ions). When ozonide ions come into contact with water, they immediately become hydroxyl radicals and decompose organic matter in the water. The use of a catalyst further increases the treatment efficiency to nearly 20 times higher than that of ozone.

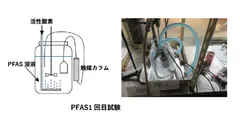

PFAS treatment using the active oxygen catalyst

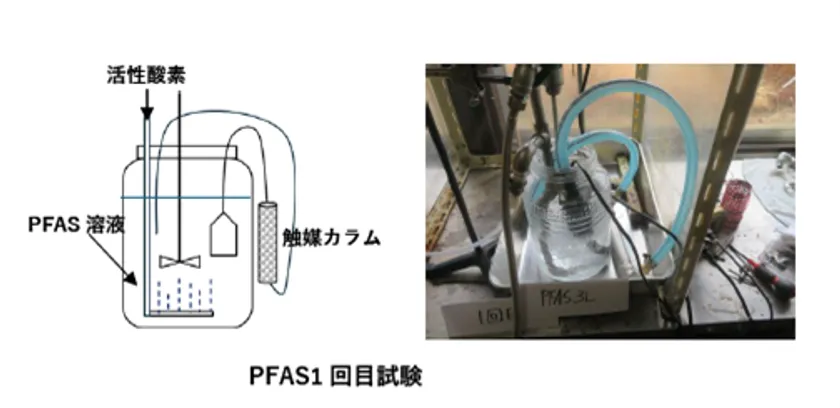

A test solution of PFOS (50 μg/L) and PFOA (50 μg/L), which was custom-made by an analytical laboratory, was placed in a container, and active oxygen was supplied by a diffuser tube and the solution was stirred to increase contact efficiency. The catalyst was placed in a column and the PFAS solution was circulated by a submersible pump.

Treatment details

Treated water: 3 L of mixed solution of PFOS (50 μg/L) and PFOA (50 μg/L)

AOS : ozone = 6:2, catalyst: 50 g

Image (6) Active oxygen catalyst treatment

■Test results

Image (7) Test results

TERRAST" and "Active Oxygen Catalyst" treatments are highly anticipated.

PFAS diffuse widely in the environment and dissolve in water. Inevitably, the amount of PFAS-contaminated water that must be treated is significant, and the introduction of activated carbon adsorption, ion exchange resin, and reverse osmosis membrane treatments, which are currently considered feasible, has been hesitated due to cost considerations.

In the case of the TERRAST treatment, simply circulating the treatment tank and TERRAST is maintenance-free for 6 months, and since almost only the PFAS in the water precipitates, the amount of precipitation is small and can be separated and recovered reliably. The small amount of precipitation means that the load for secondary treatment (incineration, etc.) is greatly reduced.

In the case of "activated oxygen catalyst treatment," both activated oxygen and ozone are derived from oxygen in the air, so there is no need for maintenance. PFAS and other organic components adsorbed on the catalyst are almost completely decomposed, so the catalyst does not need to be replaced (performance check once a year). Since the activated oxygen treatment is a complete oxidative decomposition, no secondary treatment is required.

The reason why the PFOA treatment was less effective in this test may be due to the difference in the added acid, etc. We are considering re-testing with a catalyst that adsorbs PFOA well.

By increasing the amount of TERRAST or active oxygen catalyst in proportion to the amount of water treated, it will be possible to handle large volumes of treated water.

If incineration of PFAS extracted and concentrated by TERRAST is difficult, we believe that a two-stage use of active oxygen catalyst treatment would be effective.

Looming Regulations and Responsibility

PFAS have been used for decades in the production of consumer products, foam extinguishing agents, and fluoropolymers. PFOA and PFOS are no longer used or produced in Japan, but they contaminate drinking water sources throughout the country.

As their effects on human health become more and more apparent, regulations will become more and more stringent. There are a number of technologies that could be used to clean up PFAS, and we hope you will consider ours as one of them.

Company Profile

Company name: WEF Technology Development Co.

Representative: Akira Aoyama, President

Location: 1-19-15 Do, Otsu-shi, Shiga

Establishment : July, 2016

Business description: Water treatment, waste recycling, sterilization and freshness preservation,

Development of high-efficiency, environmentally friendly, low-impact engines, etc.

URL : https://aoyama-wefit.com

https://mgworld.aoyama-wefit.com/ (Magnesium World)

- Category:

- Corporate Trends